–Overview of the Chloride Process TiO₂ Industry–

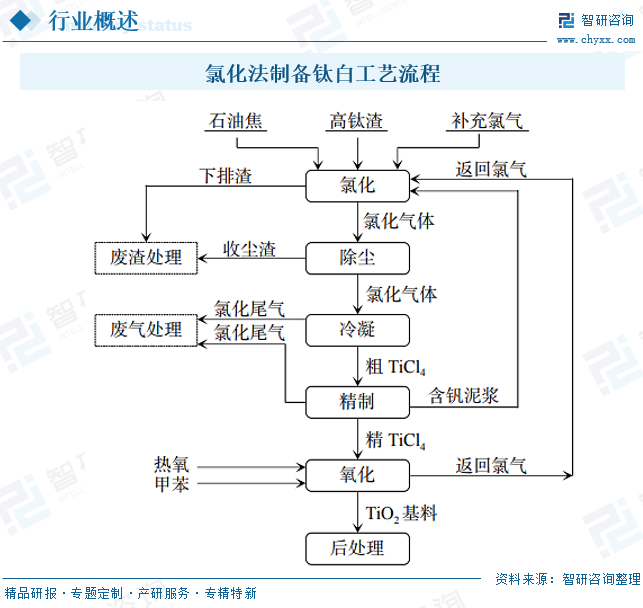

Chloride process TiO₂ is a titanium dioxide (TiO₂) pigment produced through the chloride process. The production process starts with titanium concentrate or high-titanium slag as raw materials, which are chlorinated to form titanium tetrachloride (TiCl₄), followed by oxidation and post-treatment steps to produce the final product. The tio2 chloride process, compared to the sulfate process, offers advantages such as lower emissions, higher product quality (including higher purity, better whiteness, and uniform particle size), and continuous production. It is particularly suitable for high-end applications such as coatings, automotive paints, and plastics.

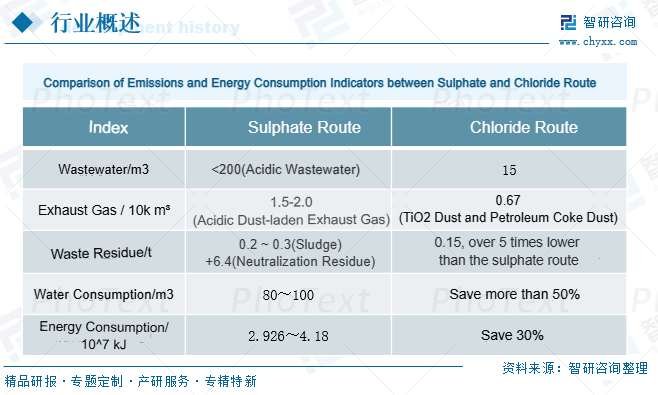

Compared to the sulfate process, the chloride process offers significant advantages in reducing pollutant emissions and energy consumption, making it more aligned with the current requirements for green manufacturing development.

Some parts of this post are password-protected. You can obtain the password through either of the following methods:

- Request it via email at info@etio2.com.

- Join the LinkedIn group “TIO2 WORLD – Titanium Dioxide” for ACCESS CODE.